[Editor’s Note: Today’s post by guest blogger Jeremy McLain was initially submitted as an entry to our recent Mad Scientist Operational Environment in 2035 Writing Contest. As we learned from our previous post by Chris Elles, decisive advantage is now only achievable by accelerating the delta-v velocity of our adaptability vice that of our adversaries. The subjects of Mr. McLain’s post — the 4th Industrial Revolution and Additive Manufacturing — are the twin accelerants that promise to push innovation and adaptability all the way to the firewall, facilitating rapid prototyping and customization, while brushing aside old paradigms of exquisite weapon system acquisition, fixed tables of organization and equipment (TO&E), and extended supply chains. These accelerants are double-edge, however, as they will empower lesser states and non-state actors alike to “punch above their weight” — enabling them to rapidly experiment with and converge new technologies to produce and deploy innovative capabilities threatening asymmetric overmatch. This won’t be your father’s (or mother’s) Operational Environment!]

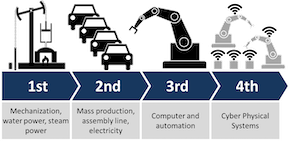

In general, the 4th Industrial Revolution encompasses several emerging and interacting technological trends blurring the lines between digital and physical realms. “Industry 4.0” is made up of trends in “artificial intelligence, robotics, the Internet of Things, autonomous vehicles, 3-D printing, nanotechnology, biotechnology, materials science, energy storage, and quantum computing.” 1

3D Printing or Additive Manufacturing (AM) and various related digital fabrication technologies will impact the Operational Environment and by extension, national security.

In an article in the National Defense University’s Defense Horizons periodical Sept 2012 article entitled “Toward the Printed World: Additive Manufacturing and Implications for National Security,”2 the authors point out several security implications with wide-spread 3D printing capabilities. On the positive side, the paper identified several things which will be positive for national security. More and smaller-sized companies could be involved in production and provision of services to government. An identified area worth investigating is the use of 3D printing for Humanitarian Assistance/Disaster Relief operations. On the negative side, the technology may also be used for criminal or adversarial applications. Other implications on national security and the Operational Environment are the following:

Lead-Time technology superiority advantage erosion: Since competitors will have or soon have access to the same tools that the US and Allies have, the lead-time of technology superiority would be diminished. Thus, the investment equation will change. As the weapon, counter-weapon, counter-n cycles back and forth, 3D printing and rapid prototyping will play a key role in solutions development on both sides. This “Red Queen effect” in war has been cited by several academics. Neil Johnson studied the cycles of IED attacks in Iraq and published his findings in a paper entitled “Patterns in Escalation in Insurgent and Terrorist Activity” 3. The main gist of the paper is what most have come to intuitively know. That is, the cycle of weapon, counter-weapon, counter-counter, etc. is getting shorter as both sides learn to adapt. With the application of wide-spread 3D printing technology, it will be expected that this evolutionary cycle will get faster since it enables quick concept prototyping and testing.

Empowered individuals: The 4th Industrial Revolution will also enable bad actors to create and make weapons or other dangerous implements with the ease of pushing a button. In prior industrial paradigms, the ability to make a complex and sophisticated weapon system would have been only available to large companies and governments with the capital equipment and know-how to produce such items.

Empowered individuals: The 4th Industrial Revolution will also enable bad actors to create and make weapons or other dangerous implements with the ease of pushing a button. In prior industrial paradigms, the ability to make a complex and sophisticated weapon system would have been only available to large companies and governments with the capital equipment and know-how to produce such items.

“Improvised Everything”: In a brief 4 given by Drs. Allan Steinhardt and David Smith from Booz Allen Hamilton, the author cites many examples of the enemy combatants (in this case during Operation Iraqi Freedom/Operation Enduring Freedom) utilizing weapons improvised by modifying commercial products. With the introduction of AM and increasingly capable desktop 3D printers, it is not far-fetched to foresee that 3D printing would be utilized to make ad hoc weaponry for use by insurgents or other future emergent threats. Already there are movements to “liberate” 3D data for anybody to use, whether for good or ill. In 2012, Pirate Bay 5, a popular website for swapping pirated content such as music and video, added a section called “Physibles” which is for trading of 3D printable media, ostensibly to infringe others’ Intellectual Property rights for physical objects.

In the defense-related arena, an outfit called Defense Distributed 6 is dedicated to developing 3D data for functioning printable “wiki weapons” such as an AR-15 and AK-47. The projects have caused much controversy and generated extensive media coverage. An early version of the AR-15 receiver was able to shoot 6 rounds before cracking. A later version of this printable receiver was able to withstand firing 600 rounds 7. Having this capability in the public domain was not such a concern in a pre-4th Industrial Revolution paradigm.

The capital requirement to make defense-related products will drop due to wide-use of 3D manufacturing technology. Thus any “leaks” of defense sensitive technology product data will do even more damage to national security. In a paper written by RAND Corporation entitled Stealing the Sword: Limiting Terrorist Use of Advanced Conventional Weapons 8, the authors argue that it is getting increasingly easier for non-state actors to get their hands on advanced weaponry once reserved for nation-state armed services. This will be even more the case as the data used in making these systems become 3D printable. Most weapons are developed with ruggedness and durability in mind, but with the advent of printable one-time-use weapons, these considerations will not drive the design, but their usefulness for insurgency.

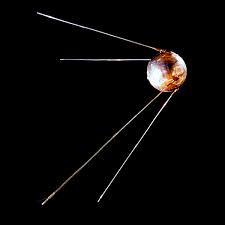

Increased chances of tech surprise: As the realm of the technologically possible expands while, simultaneously, the tools for innovation become easier and cheaper to utilize by everyone, the chances and frequency of technology surprise will increase. A positive side-effect would be increasing economic development and growth, which is needed to solve the US fiscal situation and is cited by the DoD itself as a national security issue 9. The  most famous example of technology surprise is the launch of the Soviet satellite “Sputnik” in 1957, which surprised many in the US. The shock spurred the US to start several initiatives, including the formation of DARPA (then named ARPA) and NASA, along with increased funding of R&D. One of DARPA’s main charters is to maintain US technological advancement and prevent technology surprise. From a report entitled Bridging the Gap 10, DARPA states its mission thusly:

most famous example of technology surprise is the launch of the Soviet satellite “Sputnik” in 1957, which surprised many in the US. The shock spurred the US to start several initiatives, including the formation of DARPA (then named ARPA) and NASA, along with increased funding of R&D. One of DARPA’s main charters is to maintain US technological advancement and prevent technology surprise. From a report entitled Bridging the Gap 10, DARPA states its mission thusly:

“DARPA’s original mission, established in 1958, was to prevent technological surprise like the launch of Sputnik, which signaled that the Soviets had beaten the US into space. The mission statement has evolved over time. Today, DARPA’s mission is still to prevent technological surprise to the US, but also to create technological surprise for our enemies.”

In a report from the National Research Council entitled Avoiding Surprise in an Era of Global Technology Advance 11, the authors documented several findings. The first was that increasingly evolving technological advances are being driven by non-governmental and international technical communities. Another was that the array of possibly important technologies is “vast and diverse,” which is a challenge with respect to technology warning.

Backing this up is the 2019 Global R&D Forecast 12 issued annually by R&D Magazine. The US spends roughly a quarter of global R&D spending. However, as more developing countries become more advanced, the percentage of US R&D will shrink relatively to the rest of the world, even as total and US R&D will continue to grow absolutely. As AM enables faster and cheaper development and research of new products, many of these high technology products will come from global sources.

Backing this up is the 2019 Global R&D Forecast 12 issued annually by R&D Magazine. The US spends roughly a quarter of global R&D spending. However, as more developing countries become more advanced, the percentage of US R&D will shrink relatively to the rest of the world, even as total and US R&D will continue to grow absolutely. As AM enables faster and cheaper development and research of new products, many of these high technology products will come from global sources.

Requirements: AM will facilitate the manufacture of technological systems suited for their specific environment, instead of poorly suited to all environments. The advent of systems being able to be printed “at will” will greatly change the interplay between requirements development and solutions development. The process of solutions development will become faster, which will necessitate that requirements be identified and validated faster.

R&D Processes: In general, the use and development of additive prototyping will greatly accelerate the capability of R&D phases to produce working prototypes. Integration of “higher fidelity” rapid prototyping along with faster modeling and simulation capability will enhance our ability to perform iterations with higher frequency and variety in order to optimize or update a design. Weapons could be optimized/ customized for theater of use (cold/hot, jungle, desert, etc.) as needed. Customization could even reach down to the individual soldier to account for human factors such as arm length and height. An active user community would also play a greater role in modification and idea incorporation for later versions of a design. The removal of “Design for Manufacturability” as a design constraint will open up the design-space. Designers will be able to design products with more complex features than would have been effectively possible with traditional manufacturing. Indeed, many concept cars seen in auto shows are custom-built to show off design possibilities that would in general be too cost prohibitive to produce for mass markets.

Design, Performance, and Cost: Use of grading of parameters can be explored to enhance performance. Making systems lightweight is one of the highest priorities to enhance Soldier endurance as well as to lessen logistics burdens (i.e., transportation costs). Use of plastics, metal, and composites where heavy structural materials are traditionally used can now be investigated.

Graded materials can be used to reduce weight by taking out materials where not needed. Non-traditional materials can be explored for use in arms and munitions. As making complex material matrices is advanced, other structures can be made lightweight. Heavy support structures could be made more lightweight using these advanced methods. AM can bring down the costs of systems development, production and sustainment.

Engineering and Manufacturing Development: During the Engineering and Manufacturing Development Phase (EMD), wider spread applications of AM will have several implications. As with the wars in Afghanistan and Iraq, the use of Urgent Materiel Release would become a rule rather than the exception. AM will speed up our ability to develop and implement solutions and facilitate additional design upgrade cycles. As requirements change due to user-feedback from the field, testing of each new configuration will become cost prohibitive. Testing will be relegated for safety, while Modeling & Simulation would be used to re-qualify the upgraded design configuration.

Sustainment and Training: In sustainment logistics, additive manufacturing may find many uses. A much touted emergent capability would be print out spare parts in the field. Support for legacy systems is also greatly enhanced to produce obsolete parts. Another application could be rapid prototyping of in-field tools for use by maintenance personnel. For training, prototype-mockup concepts for system familiarization and feedback are useful, especially earlier in the developmental process. One paradoxical feature is that it will allow parts that are designed now to never become obsolescent. Thus, new upgrades have to be re-qualified for a system every so often which can be cost-prohibitive. With the nascent printed electronics developments, the obsolescence problem would be resolved. This entails a paradox. The development of printed parts enables higher upgrade/design cycles (like software releases) but at the same time allows no earlier iterations to become obsolete as the CAD data can remain stored and accessed if needed for support of legacy systems. There are other gains in logistical sustainment. In situ or just-in-time production and fielding means minimal storage and handling which in turn saves logistical costs. The effects of faster innovation cycles will increase parts obsolescence issues which already plague many systems. As many systems, especially large systems which take 20 years to develop, many parts are obsolete and cannot be bought as industry has moved on. This necessitates having to re-qualify new parts for a system. As the cycle-time dwindles, there might not be enough time for a “requalified” part to last long in the supply chain before it becomes obsolete again. The silver lining is that with the “Long Tail” 3D Print-on Demand manufacturing, many parts will never become obsolete, in regards to manufacturability where the parts can be reproduced from digital CAD data. The development of additive manufacturing cells in-field will most likely develop into an MOS (Military Occupational Specialty) for “3D Printer Technicians” which would run in-field production of spare parts as well as maintain the printers.

Conclusion: The rate of technological change is accelerating. Advances in various technologies to include additive manufacturing are interacting with each other and with social trends to increase innovation and variety within the economy. As with any revolution, it is expected that new technology paradigms will be created which will replace current technology paradigms. Organizations and individuals will need to adapt and position themselves to take advantage of the interacting trends making up the 4th Industrial Revolution.

If you enjoyed this post, check out:

Mission Engineering and Prototype Warfare: Operationalizing Technology Faster to Stay Ahead of the Threat, by Dr. Rob Smith and Messrs. Shaheen Shidfar, James Parker, Matthew A. Horning, and Thomas Vern

The Iranian Pursuit of Military Advantage: A Forecast for the Next Seven Years; The Hermit Kingdom in the Digital Era: Implications of the North Korean Problem for the SOF Community; and Extremism on the Horizon: The Challenges of VEO Innovation by Colonel Montgomery Erfourth and Dr. Aaron Bazin

Table of Future Technologies: A 360 Degree View Based on Anticipated Availability by Richard Buchter

>>> REMINDER 1: The Mad Scientist Initiative will facilitate the next webinar in our Weaponized Information Virtual Events series in two weeks on Wednesday, 15 July 2020:

>>> REMINDER 1: The Mad Scientist Initiative will facilitate the next webinar in our Weaponized Information Virtual Events series in two weeks on Wednesday, 15 July 2020:

AI Speeding Up Disinformation — This virtual panel will be moderated by LTG John D. Bansemer (USAF-Ret.), and will feature Dr. Margarita Konaev, Katerina Sedova, and Tim Hwang, all from Georgetown University’s Center for Security and Emerging Technologies.

In order to participate in this virtual webinar, you must first register here [via a non-DoD network].

>>> REMINDER 2: We will facilitate our Weaponized Information Virtual Conference, co-sponsored by Georgetown University and the Center for Advanced Red Teaming, University at Albany, SUNY, on Tuesday, 21 July 2020. The draft agenda for this event can be viewed here. In order to participate in this virtual conference, you must first register here [via a non-DoD network].

>>> REMINDER 3: If you missed participating in any of the previous webinars in our Mad Scientist Weaponized Information Virtual Events series — no worries! You can watch them again here [via a non-DoD network].

Jeremy McLain is an S&T Cooperation Manager at the US Army’s CCDC Armaments Center where he is responsible for planning, development, coordination of international R&D agreements and cooperative projects with foreign governments, academia, and industry. Prior to working in International Cooperation, Mr. McLain worked in the Non-Lethal/Scaleable Effects Branch where he developed non-conventional weapons for Non-Lethal Incapacitation and for Military Operations in Urban Terrain (MOUT). He graduated from Arizona State University in 2000 with an undergraduate degree in engineering and subsequently earned a master’s degree in engineering from Stevens Institute of Technology in Hoboken, New Jersey.

Disclaimer: The views expressed in this blog post are those of the author, and do not necessarily reflect those of the Department of Defense, Department of the Army, Army Futures Command (AFC), or Training and Doctrine Command (TRADOC).

1 Schwab, Klaus (2016, 01 14) “The Fourth Industrial Revolution: what it means, how to respond” Retrieved from https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond/.

2 McNulty, C. M., Arnas, N., & Campbell, T. A. (2012). Toward the printed world: Additive manufacturing and implications for national security. Defense Horizons, (No. 73), Retrieved from https://apps.dtic.mil/dtic/tr/fulltext/u2/a577162.pdf

3 Johnson , N. (2011). Pattern in escalations in insurgent and terrorist activity. Science, Vol. 333 (no. 6038), pp. 81-84. doi: DOI:10.1126/science.1205068

4 Steinhardt, A. & Smith, D. (n.d.). “improvised everything”: the changing role of advanced technology in warfare. [powerpoint slides] Retrieved from http://www.wired.com/images_blogs/dangerroom/files/090908WIREDImprovisedEverything_Revised.ppt

5 Ludwig, S. (2012, 01 24). The pirate bay launches crazy physibles category for printing 3d objects. VentureBeat, Retrieved from http://venturebeat.com/2012/01/24/pirate-bay-physibles-category-3d-printers/

6 Defense distributed. (n.d.). Retrieved from http://defensedistributed.com/

7 Beckhusen, R. (2013, 02 28). Watch the new and improved printable gun spew hundreds of bullets. Wired Magazine, Retrieved from http://www.wired.com/dangerroom/2013/02/printable-receiver/

8 Bonamo, J., Bergamo, G., Frelinger, D., Gordon, J., & Jackson, B. (2007). Stealing the sword: Limiting terrorist use of advanced conventional weapons. RAND Corporation. Retrieved from http://www.rand.org/content/dam/rand/pubs/monographs/2007/RAND_MG510.pdf

9 Pellerin, C. (2013, 01 08). DoD comptroller: Budget stability key to national security. American Forces Press Service. Retrieved from http://www.defense.gov/News/newsarticle.aspx?ID=118939

10 (2005). Bridging the gap powered by ideas. DARPA. Retrieved from http://www.dtic.mil/cgi-bin/GetTRDoc?Location=U2&doc=GetTRDoc.pdf&AD=ADA433949

11 (2005). Avoiding surprise in an era of global technology advances. Washington DC: National Academies Press. Retrieved from http://www.nap.edu/catalog.php?record_id=11286

12 2019 R&D magazine global funding forecast. (Winter 2019). R&D Magazine, Retrieved from https://www.rdworldonline.com/2019-rd-global-funding-forecast/